How to Install ThinClad Thin Reclaimed Wood Wall Paneling

Installing This Lightweight Solid Wood Wall Cladding is Easy and Efficient

ThinClad Wood Wall Paneling

Our ThinClad wood wall paneling is something special. It combines the durability and effectiveness fo solid wood tongue and groove paneling with a lightweight, economical dimension. Each plank is 3/8” thick and has a tongue and groove profile, making installation a breeze and the finished look stunning.

How to Install ThinClad Wall Paneling

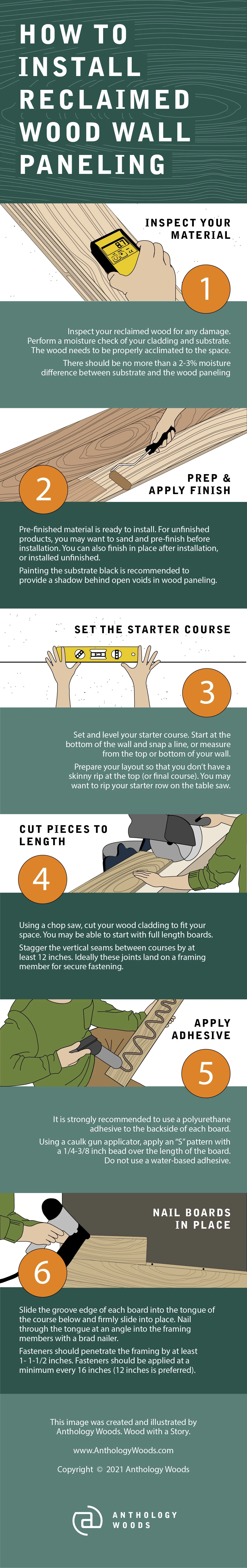

First off, it is important to inspect your product thoroughly. Is there any damage or imperfections that would inhibit installation? If so, remove the damaged planks.

Next, check the moisture content with a moisture meter. There should be no more than a 2-3% moisture difference between the substrate and the wood paneling. This ensures that the wood will be stable and won’t warp or cup during or after installation.

For best results, the wood must acclimate to the space that it is going to be installed in. We recommend acclimating the wood for at least week in the space stacked with ample airflow.

Next, get your materials and finishes together for application. If your material is pre-finished, then you are ready to move on to the next step. If you are finishing your wood paneling yourself, then pre-sand and finish the product before installing. You also may finish the product once installed, or install the product unfinished, if desired.

Prepping your surface substrate is also recommended. Installing a backing substrate, like plywood, to the wall is recommended so that the adhesive has something to bond to. Painting your substrate or wall black or another dark color helps to provide a shadow behind any voids or holes present in the wood paneling. Make sure to clean and dust your surface before installation.

Once the substrate is ready to go, it’s time to set the starter course for level installation. Start at the bottom of the wall and snap a line, or measure from the bottom or top of the wall. Prepare your layout so that you don’t have to skinny rip at the top. You may want to rip your starter course on a table saw.

Cut your wood paneling to length. Using a chop saw, cut the wood panels to fit your wall. For a staggered look, intermix longer and shorter planks. Stagger the vertical seams of the wood paneling at least 12” apart for a well-spaced composition.

Apply adhesive to the backside of the paneling, one plank at a time. It is recommended to use a polyurethane adhesive for this step to ensure a successful, long-term installation. Using a caulk gun, apply a 1/4"-3/8” thick bead to the backside of the planks in an “S” pattern. Do not use a water-based adhesive.

With the adhesive on the backside of the planks, now it’s time to nail the boards into place on the wall. Slide the groove edge of the plank into the tongue of the planks below. Nail through the tongue at an angle into the framing members with a brad nailer. Fasteners should penetrate the framing at least 1” to 1-1/2”. Fasteners should be applied at least every 16” (12” is recommended). Continue this process until the wall is complete.

ThinClad wood wall paneling is the perfect solution for a lightweight, yet durable wood wall cladding option that is easy to install and long-lasting. Most of our reclaimed and sustainable wood wall cladding is available in ThinClad dimensions, and custom dimensions and millwork are available.

If you have any questions regarding the installation process for ThinClad wood wall paneling, please contact our team. We are always here to help, every step of the way.